Email:Alisa@lantianmachine.com

Product Introduction:

Guoxin rubber tire recycling equipment is a technology that physically crushes waste tires. This technology can greatly improve the quality of waste tires after crushing, turn waste tires into reusable materials, turn waste tires into treasures, generate maximum value, thereby reducing the pollution of waste tires to the environment and contributing to environmental protection.

Factory Floor

Internal structure

The process flow of rubber tire disposal equipment mainly includes the following steps:

1. Remove the thick steel wire from the waste tire through the ring cutting machine.

2. After removing the steel wire, the tire enters the coarse crusher and breaks it into 50mm rubber blocks.

3. After the sorting machine, the rubber blocks larger than 50mm are automatically returned to the coarse crusher for further crushing.

4. The rubber blocks smaller than 50mm are transported to the medium crusher to be crushed into rubber particles below 15mm, and the fine steel wire in the tire is peeled off

5. Enter the magnetic separator to separate the rubber particles from the steel wire, and the separated steel wire is bagged and packaged, and the rubber particles enter the next process.

6. The 15mm rubber particles enter the fine crusher, which is crushed into 1-5mm particles.

7. The 1-5mm particles enter the air separator to separate the rubber particles and fibers.

8. The 1-5mm particles enter the grinding mill, which can grind 20-60 mesh rubber powder.

9. All smoke, gas and dust generated during the production process are discharged after being treated by the dust removal system, and the rubber powder enters the packaging area for packaging.

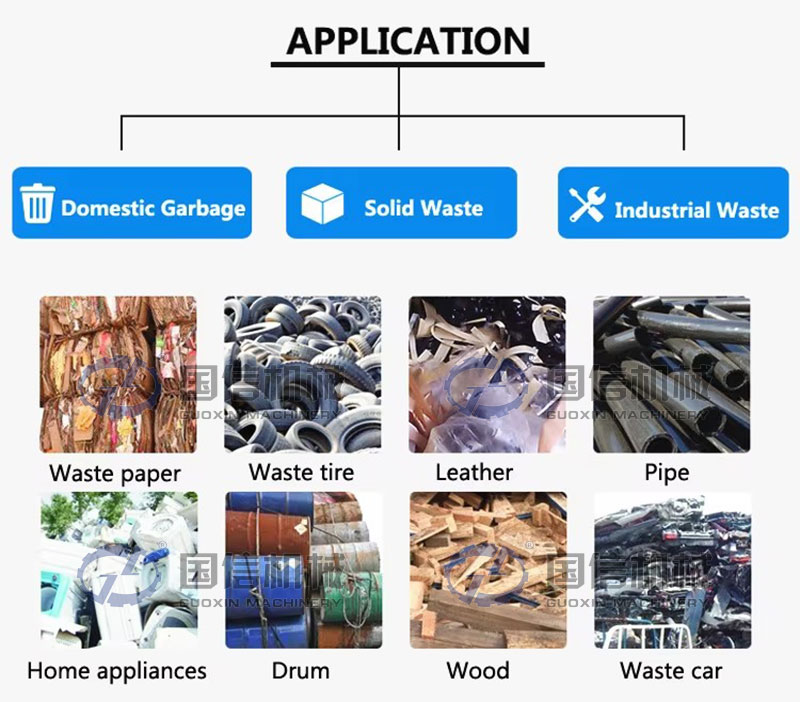

Application scope

Waste tires are widely used after being crushed.

1. Sports venues:

Rubber track (formulation, overall paving), gymnasium (molding, paving), kindergarten activity venue (molding, paving), tennis and basketball courts, sidewalks...

2. Transportation:

Tires and inner pads (layer pressing, molding and vulcanization), modified asphalt (premixed preparation)

Railway sleeper pads (molding), deceleration zones, rubber boats...

3. Daily necessities:

Elastic bands, ropes (vulcanization, tangent), rubber shoes, sneakers (paste molding, vulcanization), hot water bottles (injection molding, molding, vulcanization), raincoats, tarpaulins...

4. Cultural and sports supplies:

Tennis rackets (cutting, molding, vulcanization), printer rubber rollers (lamination, winding molding), eraser (lamination, cold vulcanization), swimming ring, basketball, football...

5. Construction and building materials:

Rubber floor tiles (molding, vulcanization), waterproof membrane (open refining, calendering, vulcanization), door and window sealing strips (calendering, vulcanization), rubber floor, mud bucket...

6. Industrial supplies:

Recycled rubber (desulfurization, open refining, refining, sheeting), V-belt (single or group molding), sealing ring (extrusion, bonding, vulcanization), hose conveyor belt...

7. Power insulation materials:

Wires, cables (extrusion, vulcanization), rubber power plugs (molding, combing), insulation sheaths (molding, vulcanization,), insulation tapes, TV high-voltage caps...

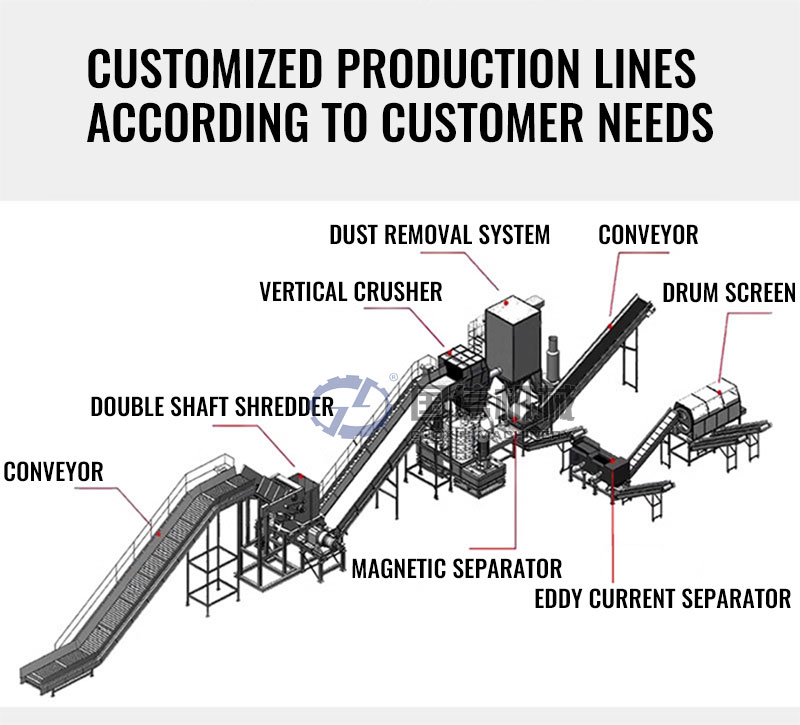

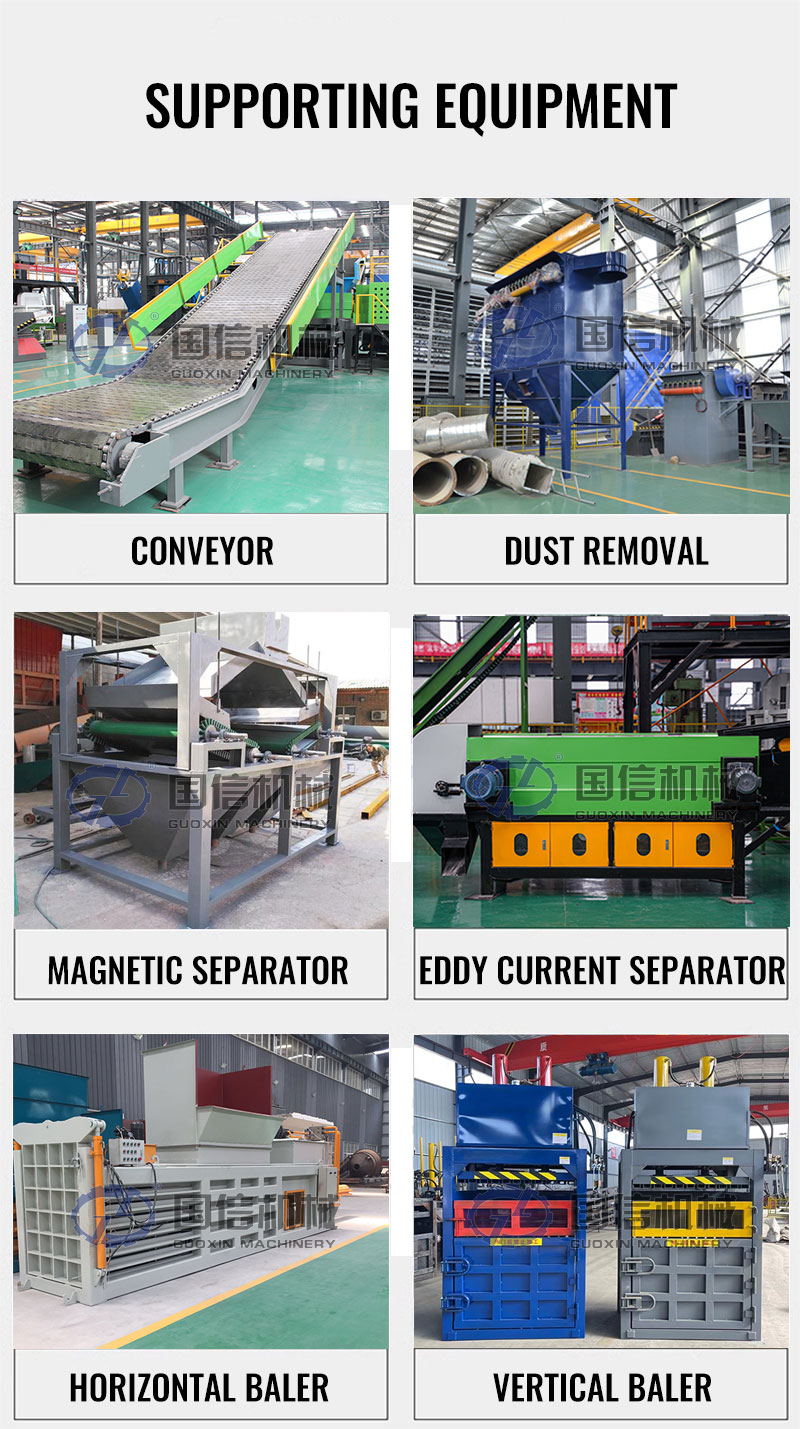

Customized rubber tire crusher equipment

1. Choose a suitable crusher according to the size, characteristics and output requirements of the crushed material.

2. Choose the appropriate material feeding and discharging methods according to the material characteristics and production site conditions.

Common feeding methods include: chain conveyor feeding, belt conveyor feeding, lifting conveyor feeding, etc. Special feeding systems can also be provided according to customer needs.

3. The machine height and discharging height can be customized.

4. Provide a variety of screens with different mesh sizes to meet the discharging particle size requirements.

Customer Case

Mongolia Customer Case

Kyrgyzstan Customer Case

Delivery site

Packaging

Inner Packaging: We can use plastic packaging if customers need

Outer Packaging: Usually wooden box or container

We can also pack the machine according to customers' needs.

Delivery Method: By Sea

Delivery Time: We respect the contract and will deliver on time as agreed for customized orders. For normal products, we have stock for immediate delivery

We are located at No. 9 Yulian Industrial Zone, Gongyi City, designing and manufacturing rubber tire recycling equipment, rubber tire disposal equipment, rubber tire crusher equipment and industrial waste recycling equipment. Our products have obtained CE and ISO certification. So far, we have exported to more than 60 countries and have a place in the world, and it is still growing.

Customer photo

We have established business plants in more than 10 countries and regions around the world, and our products are widely praised by customers for their high performance. Guoxin has been involved in the rubber tire waste recycling industry for more than 20 years. We have formed a well-trained, skilled and dedicated R&D team, which has made significant contributions to the industry and provided customers with stable and energy-saving waste reduction machines. Whether your application is garbage shredding, material recycling or solid waste crushing, Guoxin can provide you with the most suitable solution, including installation, adjustment and maintenance, making us the perfect partner.

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Email:

Alisa@lantianmachine.com