Email:Alisa@lantianmachine.com

Product Introduction:

plastic barrel shredder can meet the waste recycling and treatment of various solid waste industries. It is suitable for shredding thick, difficult to shred or large-volume materials such as: waste household appliances, waste metals, rubber tires, packaging barrels, large blue barrels, waste cars, etc. There are many types of materials that can be shredded and recycled, and it is widely practical. The shredded materials can be further refined and processed. Usually, the plastic barrel shredder machine series is used as the primary shredding equipment. It is suitable for applications in industries such as industrial waste recycling, garbage recycling, electronic manufacturing, wood processing, domestic waste recycling, plastic recycling, tire recycling, and papermaking. This plastic barrel shredding machine has the characteristics of low speed, high torque, and low noise. It adopts Siemens programming control system, can be automatically controlled, and is equipped with start, stop, reverse and overload automatic reverse control functions.

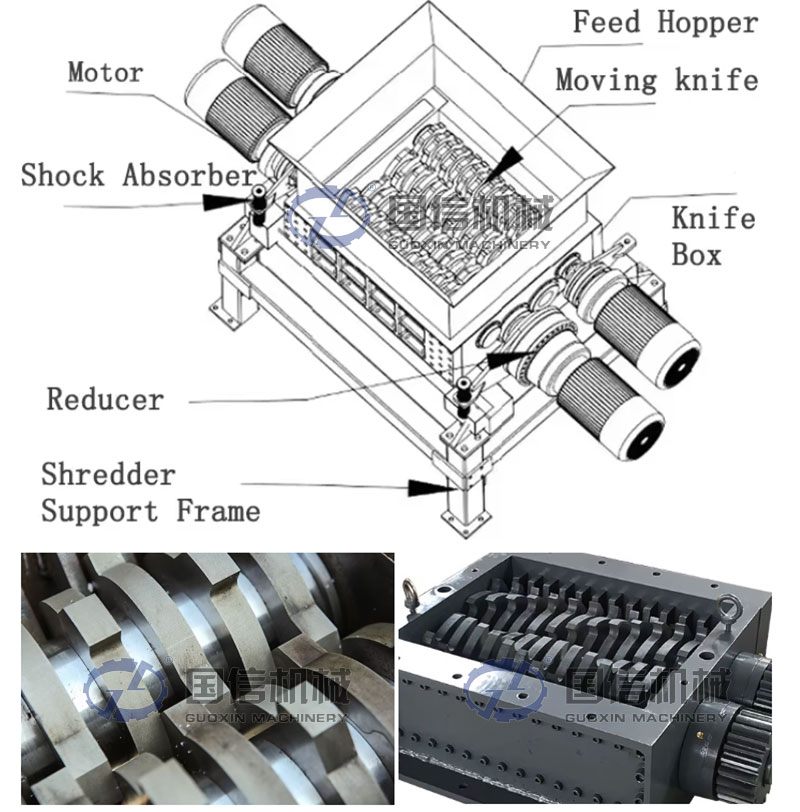

Internal structure

There are different blades to choose from depending on the product we use. The plastic barrel shredder uses double-axis blades to cut each other to meet the requirements of the shredded material. The size of the shredded material depends on the thickness and number of teeth of the shredding blade. The thinner the blade, the smaller the size of the shredded material. The more teeth, the shorter the length of the shredded material. The thicker the blade, the harder the material it can shred.

Application scope

plastic barrel shredder machine all adopt microcomputer automatic control system, equipped with start, stop, reverse and overload automatic reverse control functions, with low speed, high torque, low noise and other characteristics. The bearing seat adopts split type, which is easy to disassemble and replace the blade, suitable for shredding extra large, extra thick and difficult to shred materials.

Product advantages:

1. The thickness of the shredder blade is divided into 15mm, 20mm, 40mm, 50mm, 75mm, and 100mm. The blade can be selected according to different materials and crushed particle sizes.

2. The shredder can effectively reduce the volume of recycled garbage and facilitate transportation.

3. The price of the shredder mainly depends on the material and production efficiency. Different materials have different blades.

Customer Case

Philippines Customer Case

Taiwan Customer Case

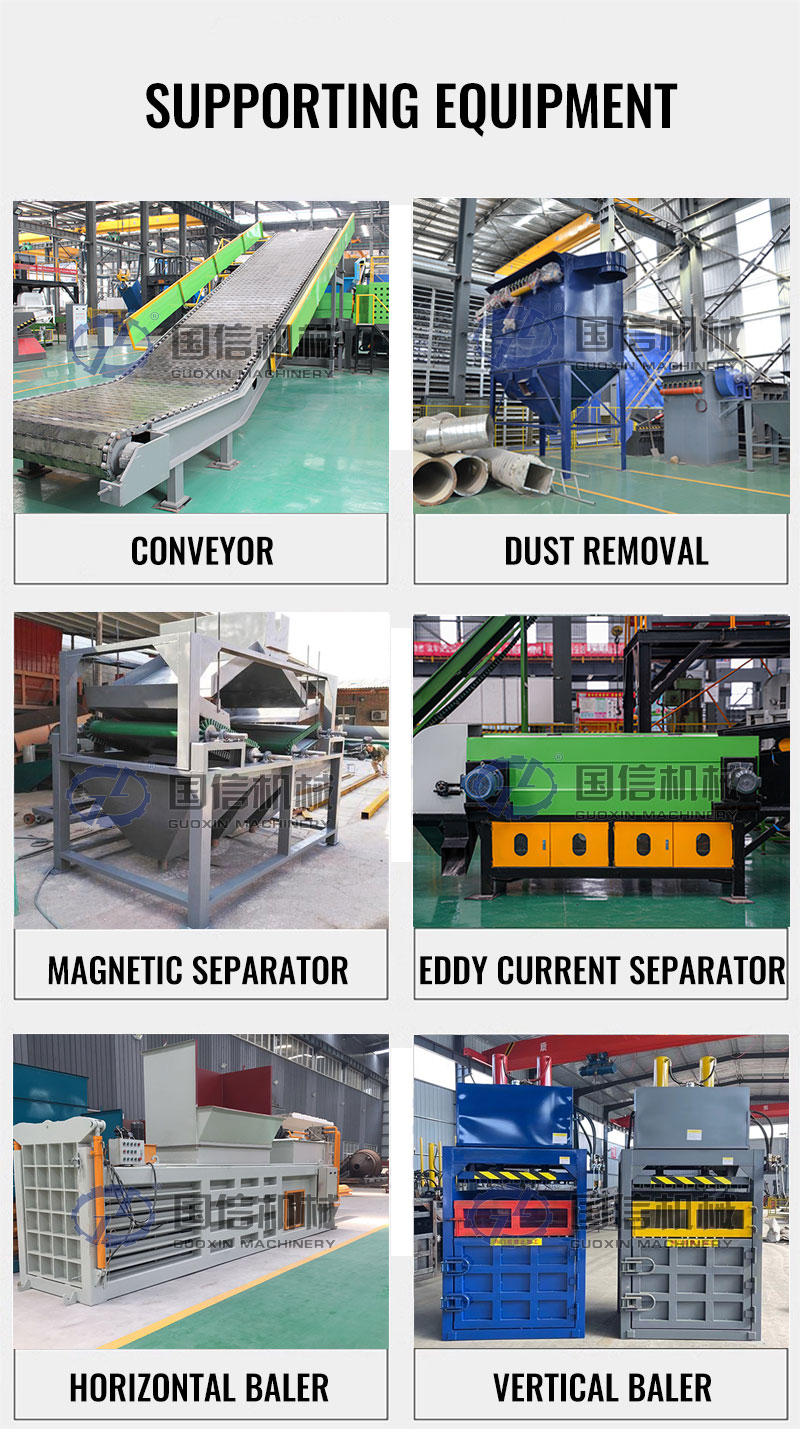

We are always working hard to design new equipment to help our customers provide better production. You can use our plastic barrel shredding machine, a fully automated production line for all kinds of waste to help customers complete the work faster and recycle more waste resources for reuse.

Delivery site

Packaging and Delivery

We provide suitable packaging solutions according to the order quantity of the goods to ensure that they will not be damaged during transportation.

The packaging can be: plywood box, steel frame box, iron pallet.. and so on.

Certificate

Customer photo

Henan Guoxin Machinery Manufacturing Co., Ltd. was established in 1999 and is a supplier of solid waste, domestic waste, metal waste, construction waste, obsolete waste and landfill waste recycling equipment.

Guoxin factory insists on customer first, machine quality first and employee first. 60% of employees have college degree.

We have exported to more than 60 countries, including the United States, Europe, Russia, India, Brazil, Nigeria, etc.

Our services:

1) Good quality control

2) Very competitive prices

3) Advanced technology products

4) Smooth communication

5) Effective OEM and ODM services

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Email:

Alisa@lantianmachine.com