Email:Alisa@lantianmachine.com

Product Introduction:

construction waste treatment equipment can conveniently and quickly realize the crushing, screening and impurity removal of construction waste. The sorted construction waste is passed through a specific iron removal device to remove the iron contained in it, and then crushed by coarse crushing, medium crushing and even fine crushing equipment to be processed into recycled sand and gravel aggregates of a certain particle size, which are used in roadbed stones, unburned bricks, cement admixtures, etc.

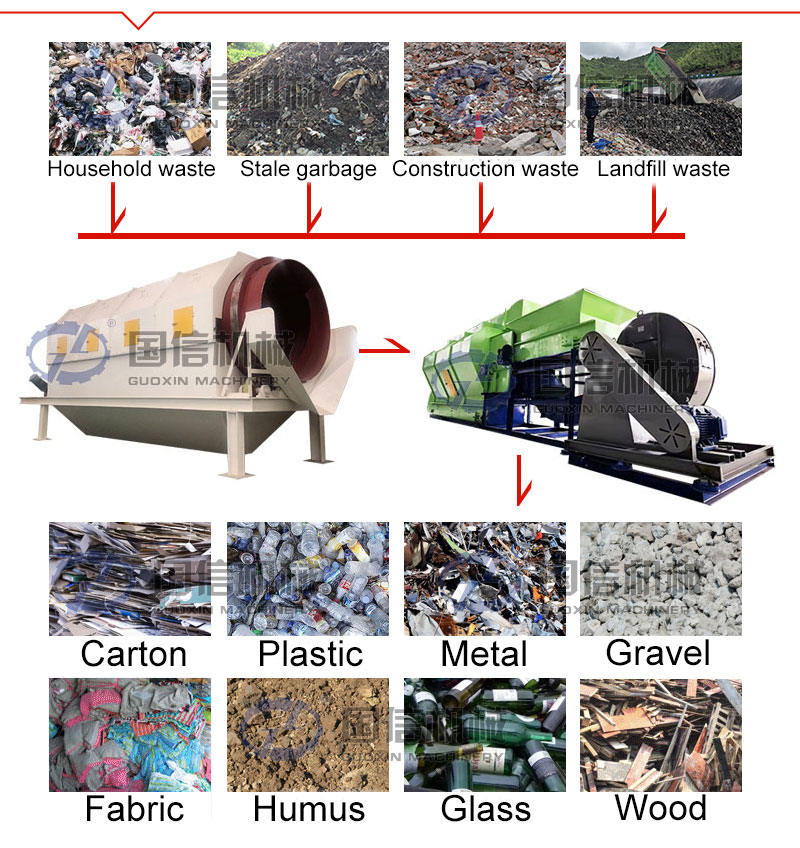

waste sorting process

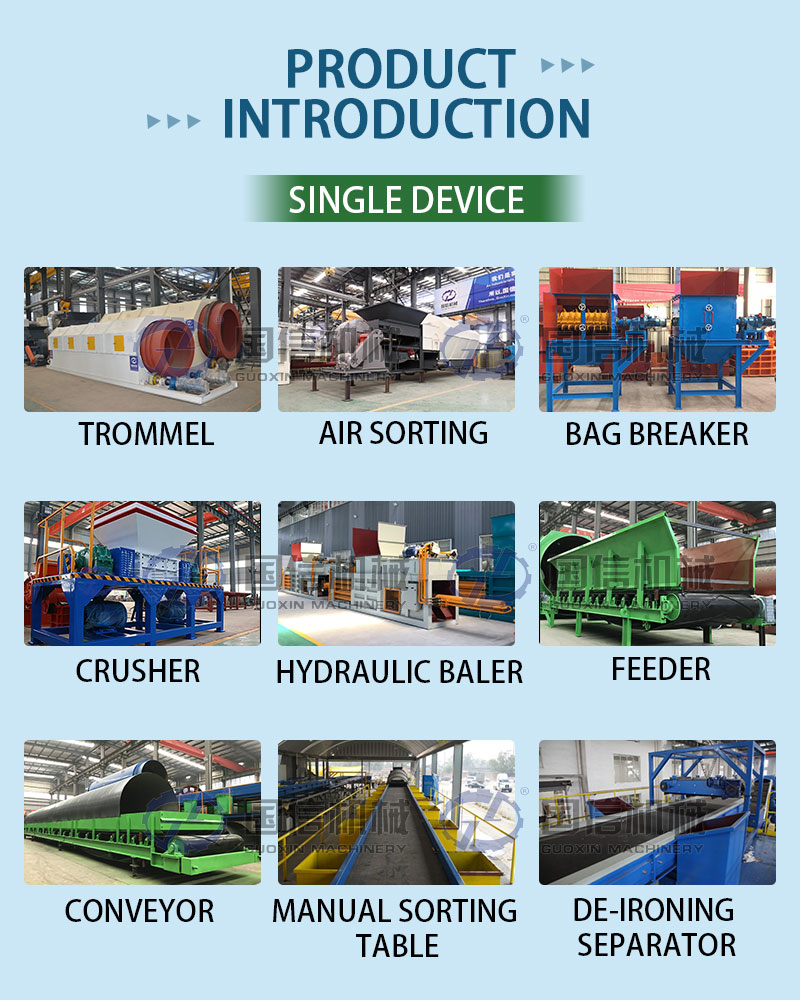

Supporting Equipment

construction waste sorting equipment application:

Crushing and screening of concrete fragments, asphalt blocks, bricks, stones, wood, plastics, plaster and mortar, steel and non-metals, etc.

Input materials: a mixture of construction waste consisting of road concrete blocks, asphalt concrete blocks, old building blocks, construction waste, etc.

Output products: iron, steel, impurities, plastics and stones and bricks of different sizes. All screened materials are used for roadbed stones, unburned bricks, cement admixtures, etc.

Customer Case

Mexican customer site

Egyptian customer site

Process description of construction waste screening equipment:

The construction waste raw materials are fed into the crusher by the feeder for crushing. The crushed materials are sent to the screening station by belt conveyor (there is an iron removal device above the belt conveyor to remove iron while conveying). After screening by the screening station, four types of materials are produced, namely 0-5mm, 5-10mm, 10-15mm, and >15mm (designed according to customer needs). Among them, 5-10mm and 10-15mm materials are light material treated before discharging, and >15mm materials are re-crushed to form a closed-loop cycle.

According to different local policies and actual environments, urban construction waste treatment can be roughly divided into two types: centralized treatment-fixed construction waste treatment system, decentralized treatment-mobile crushing and screening station.

Delivery site

Our honor

Our Services

Since the establishment of the company, we have been committed to producing high-quality, good-performance products, and have produced a series of garbage sorting equipment, our garbage disposal equipment is reasonably priced and easy to operate, and has passed ISO high-quality certification and EU CE certification.

The construction waste sorting equipment processes the concrete blocks, waste bricks, mortar, slag and other items in the garbage on site. After crushing according to the construction needs, reusable aggregates and a small amount of steel bars can be obtained. The coarse aggregate is used directly as crushed stone for foundation reinforcement, road cushions, and indoor floor cushions; the fine aggregate can be made into environmentally friendly bricks such as hollow bricks, solid bricks, square bricks, and construction waste concrete porous bricks.

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Email:

Alisa@lantianmachine.com