Email:Alisa@lantianmachine.com

Product Introduction:

tyre shredding is a pulverizing device specially used to crush rubber products. Its purpose is to crush rubber products into small pieces to facilitate the subsequent processing procedures. It is a device for crushing rubber products and waste tires. The scrap tire shredder has a high degree of automation and high production efficiency, and can enable users to use large-sized rubber economically and effectively. All rubber products that can be put into the feeding box can be directly shredded without cutting and decomposing.

Factory Floor

Internal structure

Working principle:

The spindle is supported by bearings at both ends. The motor is transmitted to the spindle through the gear box. The rotating spindle drives the spirally arranged cutters. The rotation of the spindle drives the cutters to mesh, tearing the materials into pieces and completing the cutting task. The electronic control part is equipped with an automatic reverse control device to overcome the major technical difficulties of the machine due to material jamming. In order to improve the service life and cutting ability, the spindle and cutters are tempered. The combined structure frame with precision machining of extra-thick plates, the powerful rotating shaft of the large-angle hexagonal column, and the large-diameter solid input hopper can be safely put into large raw materials. The rotary knife is uniquely designed and processed in terms of thickness, shape, and arrangement order, with strong shear force, sharp blade, and high crushing efficiency.

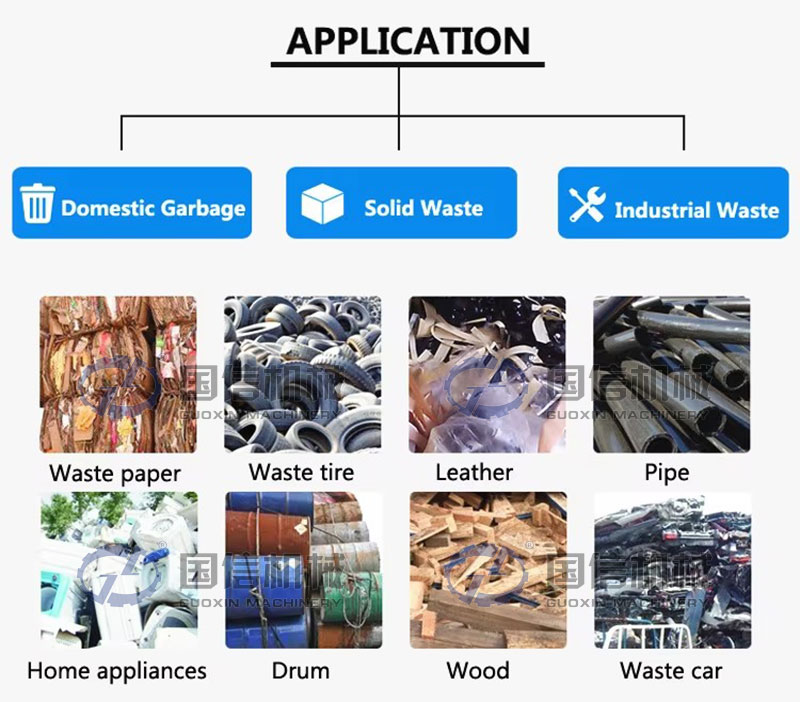

Application scope

Internal structure:

The waste tire shredding is composed of a box, a motor, an industrial gearbox, a hexagonal spindle, imported knives, a bottom knife, a frame, a bearing box and other main structures.

1. Heavy moving knives, high crushing efficiency, the knives are all cast in alloy steel, and are sturdy to use.

2. The frame plate is thick, can resist high torque, and is very sturdy.

3. It adopts microcomputer (PLC) automatic control, with start, stop, reverse and overload automatic reverse control functions.

4. The equipment has the characteristics of low speed, high torque, low noise, and dust can meet the standard.

5. Easy to adjust, low maintenance cost, economical and durable.

6. The thickness of the knife and the number of claws can be replaced according to different materials.

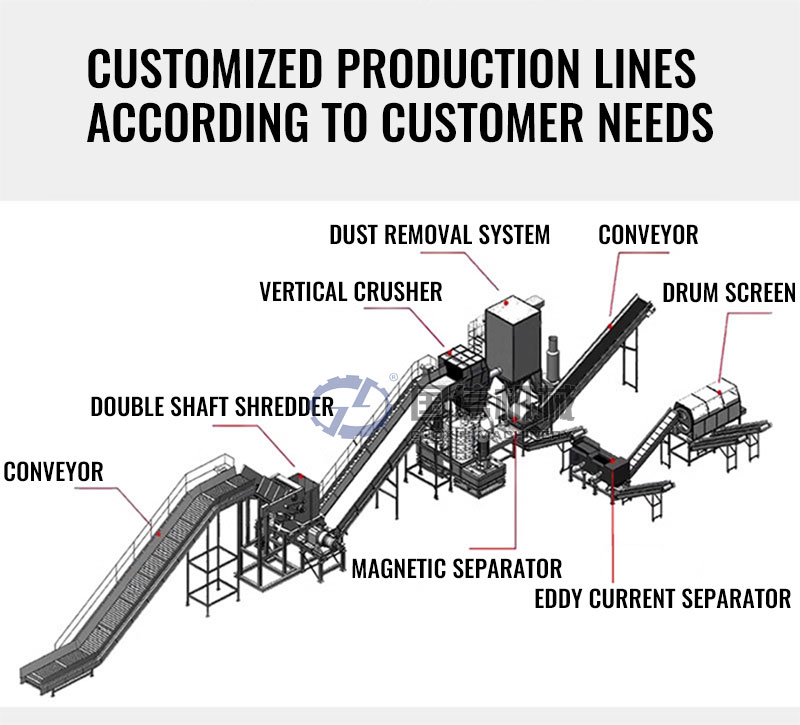

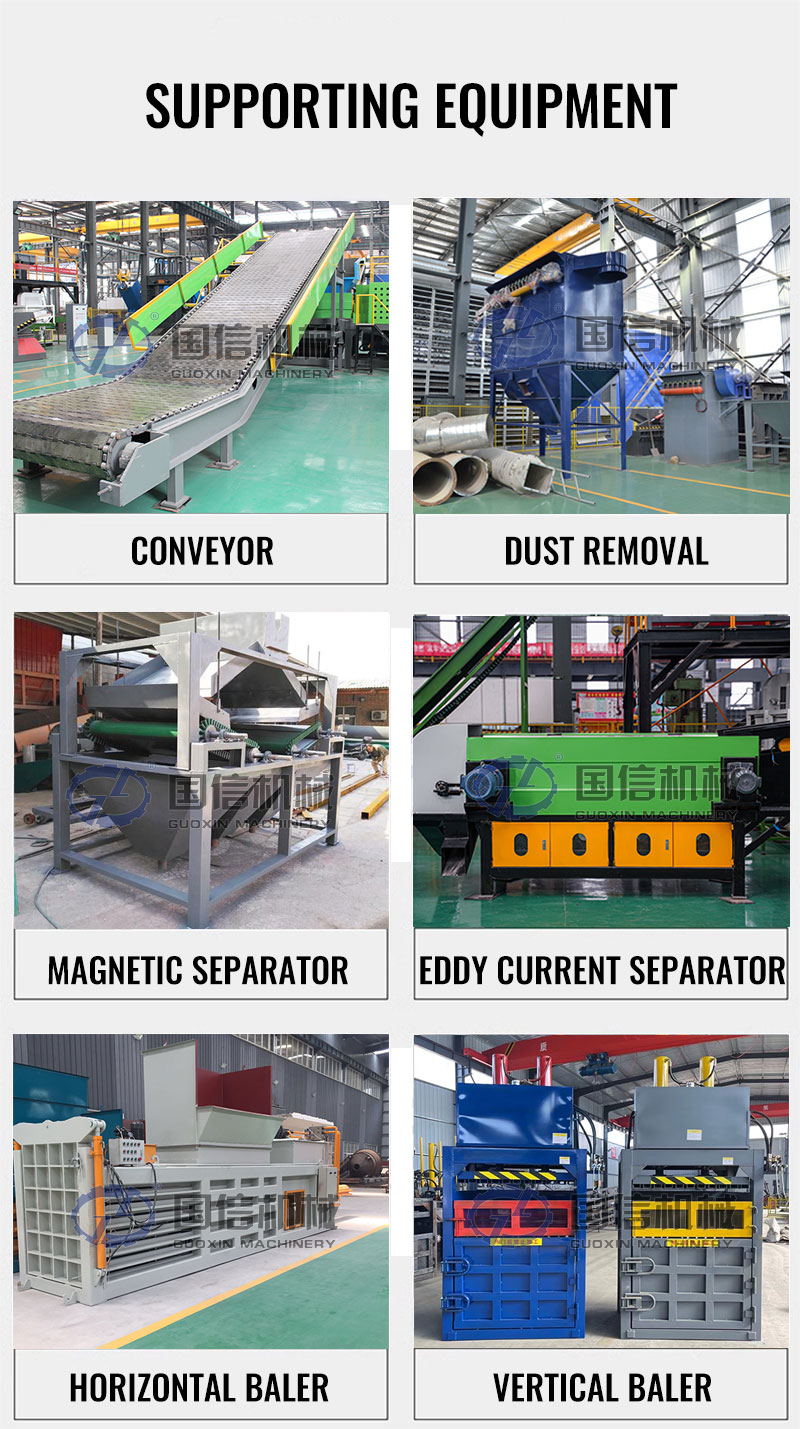

customized production line

Adjustability of shredding force

For waste tires of different materials and sizes, the adjustability of shredding force is another major feature of the tyre shredding. Users can adjust the following parameters to adjust the force according to actual needs:

Blade gap: By adjusting the gap between the blades on the two shafts, the size of the shredding can be controlled, thereby affecting the shredding force.

Shaft speed: Changing the motor speed can adjust the shaft speed, thereby affecting the shredding speed and force.

Feeding speed: Adjusting the speed of the feeding system can control the amount of material entering the shredder, indirectly affecting the shredding force.

Customer Case

Mongolia Customer Case

Kyrgyzstan Customer Case

Delivery site

Packaging of scrap tire shredder

Inner packaging: We can use plastic packaging if customers need

Outer packaging: Usually wooden box or container

We can also pack the machine according to customers' needs.

Delivery method: By sea

Delivery time: We respect the contract and will deliver on time as agreed for customized orders. For normal products, we have stock for immediate delivery

We are located at No. 9 Yulian Industrial Zone, Gongyi City. We design and manufacture tire shredders, waste tire shredders, municipal solid waste treatment equipment, domestic waste recycling equipment and industrial waste recycling machines. Our products have obtained CE and ISO certification. So far, we have exported to more than 60 countries and have a place in the world, and it is still growing.

Customer photo

We have established business plants in more than 10 countries and regions around the world, and our products are widely praised by customers for their high performance. Guoxin has been involved in the waste resource crushing, processing and recycling industry for more than 20 years. We have formed a well-trained, skilled and dedicated R&D team, which has made significant contributions to the industry and provided customers with stable and energy-saving waste reduction machines. Whether your application is garbage processing crushing, material shredding and recycling or solid waste crushing, Guoxin can provide you with the most suitable solution, including installation, adjustment and maintenance, making us the perfect partner.

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Email:

Alisa@lantianmachine.com