Email:Alisa@lantianmachine.com

Product Introduction:

large garbage sorting equipment is used to process large-sized garbage, which mainly refers to waste furniture and other non-electronic products. Waste furniture mainly includes bed frames, mattresses, sofas, armchairs, tables, chairs, wardrobes/wardrobes, bookcases and other waste living and office appliances with functions such as sitting, lying, leaning, storage, and partitioning. They are usually assembled by a number of parts and components in a certain way. In addition to wood, metal, and plastic, the materials used for furniture include rattan, bamboo, glass, rubber, fabric, decorative panels, leather, sponges, etc. Other types of large-sized garbage include kitchen utensils, bathroom utensils, bicycles, etc., as well as irregular-shaped cans, bedding, straw mats, long chain-like objects (hoses, ropes, wires, wires, etc.), etc. The materials are mainly ceramics, metals, glass, rubber, decorative panels, leather, sponges, etc.

Production line flow chart

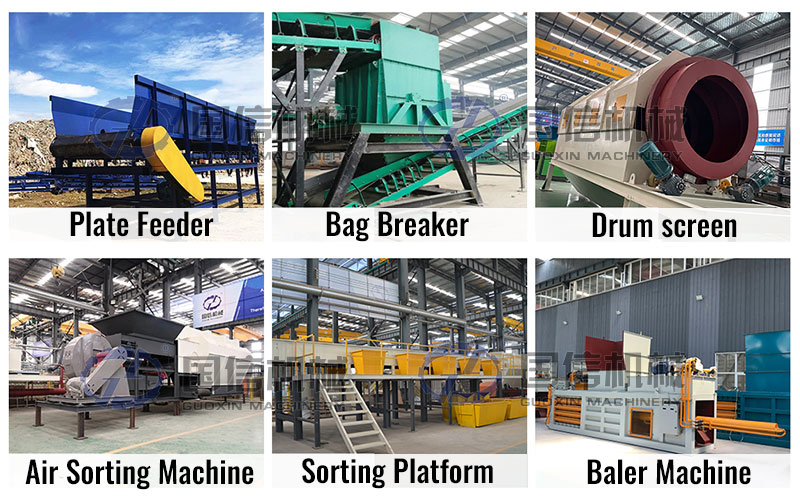

Supporting Equipment

The sorting line of large garbage treatment equipment is mainly composed of a conveying system, a sorting system, a crushing system, a compression system and a control system. Its working principle is as follows:

Conveying system: The garbage is sent to the sorting line through a conveyor belt to realize continuous transportation of garbage.

Sorting system: The garbage is sorted by using a variety of technical means such as magnetic separation, wind separation, and optical separation. Magnetic separation is mainly for metal materials, wind separation is mainly for light materials, and optical separation recognizes the color, shape and other characteristics of the objects to achieve accurate classification of garbage.

Crushing system: The sorted garbage is crushed to facilitate subsequent processing and transportation. The crushing system usually includes two stages: coarse crushing and fine crushing to meet different processing needs.

Compression system: Compress the crushed garbage to reduce the volume and reduce transportation costs. The compression system usually uses hydraulic or mechanical compressors, which are efficient and stable.

Control system: Real-time monitoring and control of the entire sorting line to ensure the normal operation of the equipment. The control system usually uses PLC (programmable logic controller) or DCS (distributed control system), which has a high level of automation and intelligence.

Large garbage

After garbage disposal

Technical features of the sorting line of large garbage screening equipment:

High efficiency and energy saving: the use of advanced sorting technology and equipment improves sorting efficiency and reduces energy consumption.

Environmental protection and safety: the entire sorting process is carried out in a closed manner, which effectively prevents secondary pollution and ensures the safety of staff.

High degree of intelligence: the control system adopts advanced PLC or DCS to realize the automation and intelligent operation of the equipment, reduce manual intervention, and improve production efficiency.

Strong adaptability: the configuration of the sorting line can be adjusted according to different garbage types and processing requirements to meet diverse processing needs.

Customer Case

Singapore Customer Case

Indonesian customer site

Application advantages of large garbage sorting equipment production line

Improve resource recycling rate: Through efficient sorting technology, recyclable materials in garbage are separated, which improves resource recycling rate and reduces resource waste.

Reduce environmental pollution: During the sorting process, hazardous garbage is separated from other garbage, which reduces environmental pollution and is beneficial to the protection of the ecological environment.

Reduce processing costs: Through crushing and compression technology, the volume of garbage is reduced, and the transportation and processing costs are reduced.

Delivery site

Certificate

Improve social benefits: The application of large garbage treatment equipment sorting line helps to improve the level of urban management, improve the living environment of residents and enhance social benefits.

Customer photo

In short, as an efficient, environmentally friendly and intelligent garbage disposal equipment, the large garbage screening equipment production line is of great significance to the development of urban garbage disposal. In the future development, we should further increase the intensity of technology research and development, improve the technical level and adaptability of the sorting line, and make greater contributions to building a beautiful ecological environment.

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Email:

Alisa@lantianmachine.com