Email:Alisa@lantianmachine.com

Product Introduction:

For scrapped cars, the choice of crushing equipment is mainly based on the early single-rotor car crusher and the existing new double-axis car shredder. As for the selection of equipment, the color plate selection is mainly based on the width index of scrapped cars, and the scrapped car shredder machine above 1000 is mainly used. This type of equipment can crush the entire car at one time.

Scrapped Cars

The car shredder can separate the lead, lead mud, plastic partitions, plastics, metals, glass fibers and other components from the scrapped cars. After the scrapped cars are dismantled, the corresponding metal blocks or metal particles are obtained, and the recovered metals are used for smelting processing in metal smelting plants.

Car shredder machine production line

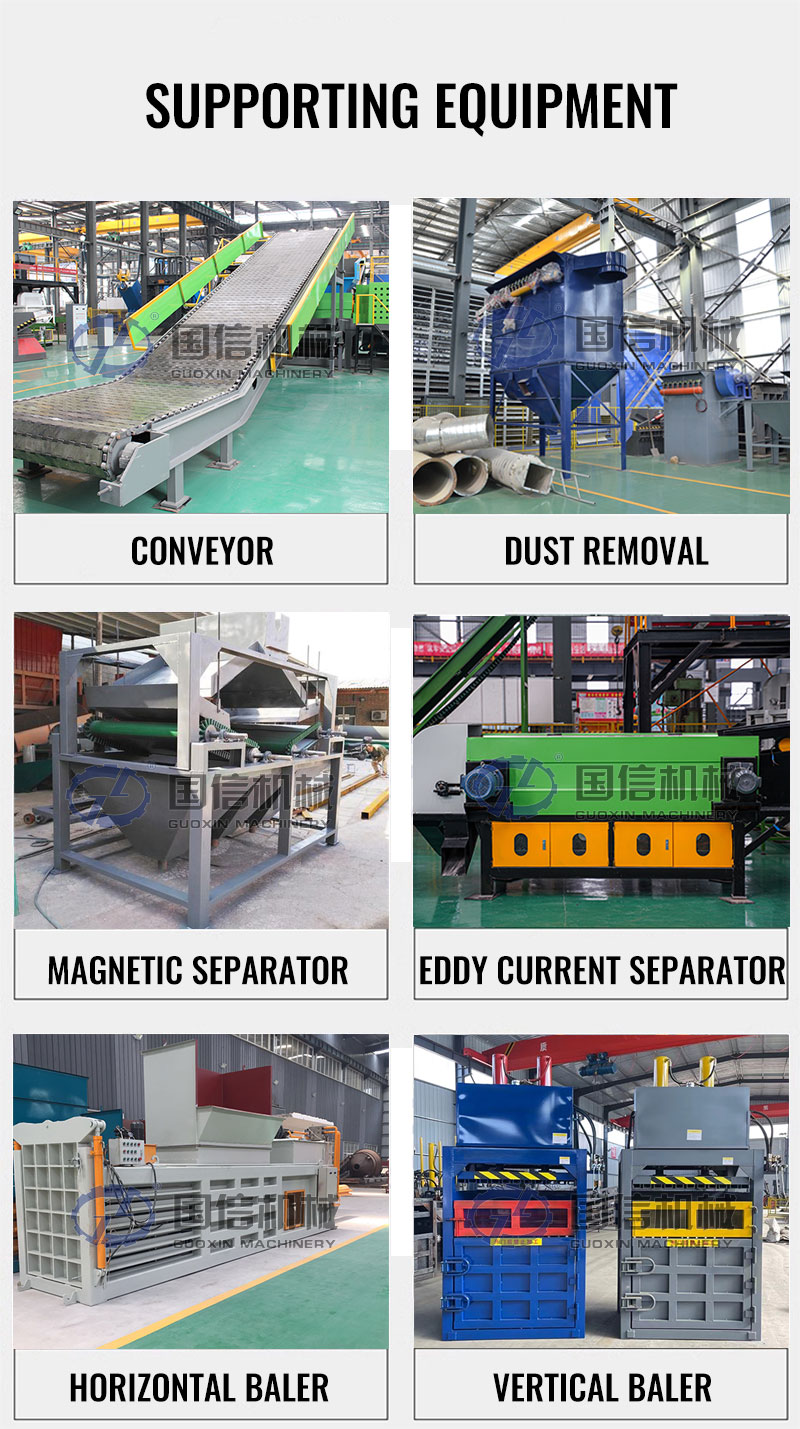

Detailed process of scrapped car dismantling equipment: The transport machinery loads the material onto the crawler plate conveyor, and the material then enters the double-drum feed roller. After extrusion and shaping, the material enters the crusher and then is sent to the discharge conveyor. At the end of the discharge conveyor, there is a wind separation and dust removal system to separate the sponge and dust in the crushed material, and then send it to the magnetic separation drum through the vibrating feeder. The magnetic separation drum separates the iron metal from the non-iron material. The iron metal is sent to the manual inspection conveyor and then to the stacking conveyor. The non-iron material falls into the non-magnetic material conveyor through the hopper at the bottom of the magnetic separation drum, and then sent to the particle screening drum to transport the medium particles to the eddy current separator to separate non-ferrous metals such as copper and aluminum from plastics and rubber. A secondary magnetic separator is set at the end of the non-magnetic material conveyor to suck out the free ferrous metal on the non-magnetic material conveyor, reduce the damage of iron metal to the eddy current separator, and improve the iron recovery rate.

Advantages of car shredder machine

1. Volume reduction: The volume of the scrap car shell is significantly reduced by shredding, which is convenient for subsequent storage and transportation. This can effectively reduce transportation costs and space occupation for the scrap car recycling industry.

2. Improve recycling rate: Shredded car shells are easier to separate and recycle materials. The metal part can be recycled, refined and reused, and the plastic and rubber parts can also be effectively processed.

3. Safety: Shredders are usually equipped with safety protection devices to ensure the safety of workers during operation and reduce the risk of accidents.

Customer Case

Mongolia Customer Case

Malaysia Customer Case

Delivery site

our honor

Since its establishment, Guoxin has always been adhering to the unremitting pursuit of excellent quality and performance, and has carefully developed and produced a series of automobile shredders. These equipment are not only reasonably priced and easy to operate, but also have obtained the dual honors of ISO high quality certification and EU CE certification. Our equipment is a powerful assistant for your business success.

In the 20 years since its establishment, the company has continuously learned new knowledge, developed new technologies, successfully launched car shredders, and won wide acclaim from customers. If you are interested in the car shredding machine price, please leave a message or contact us, and we will wholeheartedly provide you with detailed information.

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Email:

Alisa@lantianmachine.com